Advancing Lean: What to Do When the Low-Hanging Fruit Is Gone

Direct answer (TL;DR)

When the low-hanging fruit is gone, advancing Lean requires shifting from isolated waste reduction to systemic improvement by addressing cultural barriers, raising performance targets, standardizing problem triggers, and building systems that continuously surface problems. Impruver University equips teams with Lean Six Sigma training to master these advanced strategies and sustain long-term improvement.

Why Do Lean Programs Stall After Early Success?

Lean programs often stall not because they are failing, but because they are maturing. Over time, the remaining problems become harder to see, harder to solve, and more deeply embedded in organizational systems and culture.

How Impruver Helps:

- Impruver University’s Green Belt and Black Belt courses teach leaders how to diagnose maturity-related challenges and design strategies for continuous improvement beyond early wins.

- Online modules and case studies provide examples of systemic problem-solving for mature Lean environments.

What Makes High-Maturity Lean Environments More Challenging?

High-maturity Lean environments are challenging because remaining opportunities are systemic, cross-functional, and often cultural rather than technical.

Cultural Barriers and Competing KPIs

Problems often involve organizational incentives and local optimization.

How Impruver Helps:

- Training programs include modules on cross-functional metrics alignment, KPI analysis, and change management to overcome cultural barriers.

- Workshops guide teams to harmonize department-level KPIs with enterprise-level performance goals.

The Foundational Process Gap

Even experienced organizations may lack standard work or process stability.

How Impruver Helps:

- Impruver University provides structured guidance on process documentation, visualization, and standard work, ensuring your foundation is ready for advanced improvements.

- Practical exercises help participants assess and stabilize unstable processes.

How Can Organizations Uncover Hidden Waste in Mature Lean Systems?

What Are Unplanned Waste Walks?

Fresh eyes are needed to spot inefficiencies that insiders miss.

How Impruver Helps:

- Impruver courses provide frameworks for systematic observation, teaching how to conduct unplanned waste walks effectively.

- Role-playing and simulations demonstrate the value of external or cross-functional observers.

Why Is Waste Classification Important?

Correct classification accelerates problem-solving.

How Impruver Helps:

- Training includes Muda, Mura, and Muri identification exercises so teams can quickly classify waste and select the right tools.

- Participants practice matching problems to Lean or Six Sigma methods for efficient resolution.

How Should Metrics and Targets Change in a Mature Lean Program?

Why Are Stretch Targets Necessary?

Stretch targets force teams to rethink processes rather than rely on incremental adjustments.

How Impruver Helps:

- Impruver University modules cover goal-setting techniques, including stretch targets, helping teams identify opportunities that drive high-impact improvements.

- Case studies illustrate how “mission impossible” goals inspire creative process redesign.

How Do Internal Customers Improve Metrics?

Metrics should reflect what matters to downstream processes.

How Impruver Helps:

- Courses teach SIPOC mapping and internal customer feedback integration, ensuring metrics are meaningful and aligned across the organization.

- Teams learn to redefine KPIs like OTIF and error-free delivery from the customer’s perspective.

How Can Lean Projects Be Triggered Automatically?

What Does Standardized Problem Triggering Look Like?

Data should initiate improvement work, not ad-hoc observations.

How Impruver Helps:

- Training provides methods for designing automated triggers using process and event data.

- Practical exercises teach participants to implement proactive CI alerts and workflow automation.

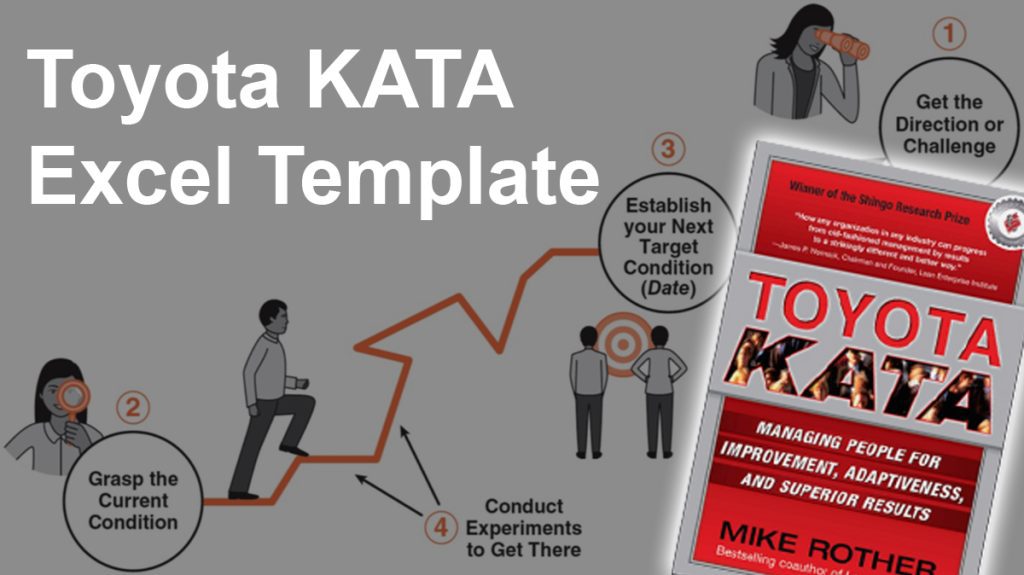

How Do You Match the Right Tool to the Problem?

Not all problems require advanced analysis.

How Impruver Helps:

- Impruver University teaches tool selection frameworks, ensuring teams use simple solutions for routine issues and reserve advanced methods for high-value variations.

- Real-world examples illustrate effective allocation of CI resources.

What Mindset Shift Is Required Beyond the Low-Hanging Fruit?

Shifting from “heroic problem hunting” to “systemic problem farming” is key.

How Impruver Helps:

- Leadership programs guide managers in building systems, culture, and infrastructure to cultivate continuous improvement organically.

- Participants learn to design scalable Lean systems that automatically surface improvement opportunities, reducing reliance on individual heroics.

Key Takeaways

- Lean programs stall because they mature, not because they fail

- High-maturity environments require systemic and cultural solutions

- Hidden waste must be deliberately surfaced through fresh observation

- Stretch targets and customer-defined metrics reignite improvement

- Standardized triggers replace ad-hoc problem solving

- Sustainable Lean shifts from “hunting” problems to “farming” systems

How Impruver Helps:

- Impruver University provides the training, tools, and practical exercises that enable teams to advance beyond early wins and sustain high-impact Lean programs.

- From Green Belt to advanced problem-solving, our courses equip leaders to thrive in mature Lean environments.

Responses